In many manufacturing companies, a significant share of planning potential remains untapped. Tools, molds, or inspection equipment determine every day whether a production line runs or comes to a standstill and therefore have a direct impact on delivery reliability, asset productivity, and costs. Although they represent critical bottleneck resources, they are often not considered in production planning. The consequences range from unplanned downtime and costly ad-hoc measures to inefficient shop floor operations.

This is exactly where our solution for SAP PP/DS comes in. By consistently applying finite planning to production resources, companies increase the stability of their production processes, reduce operational costs, and improve overall resource utilization. The effects are immediately visible and sustainable at the same time.

Why finite tool planning is crucial in SAP PP/DS

Production resources are central assets in manufacturing. If they are not planned in an integrated manner, gaps emerge in the process. Typical consequences include unplanned downtime, additional costs caused by short-term procurement, lack of transparency regarding location and utilization, and unused potential in maintenance or alternative usage.

SAP PP/DS provides a strong foundation for detailed scheduling, but it does not support finite tool planning out of the box. Our solution closes this gap.

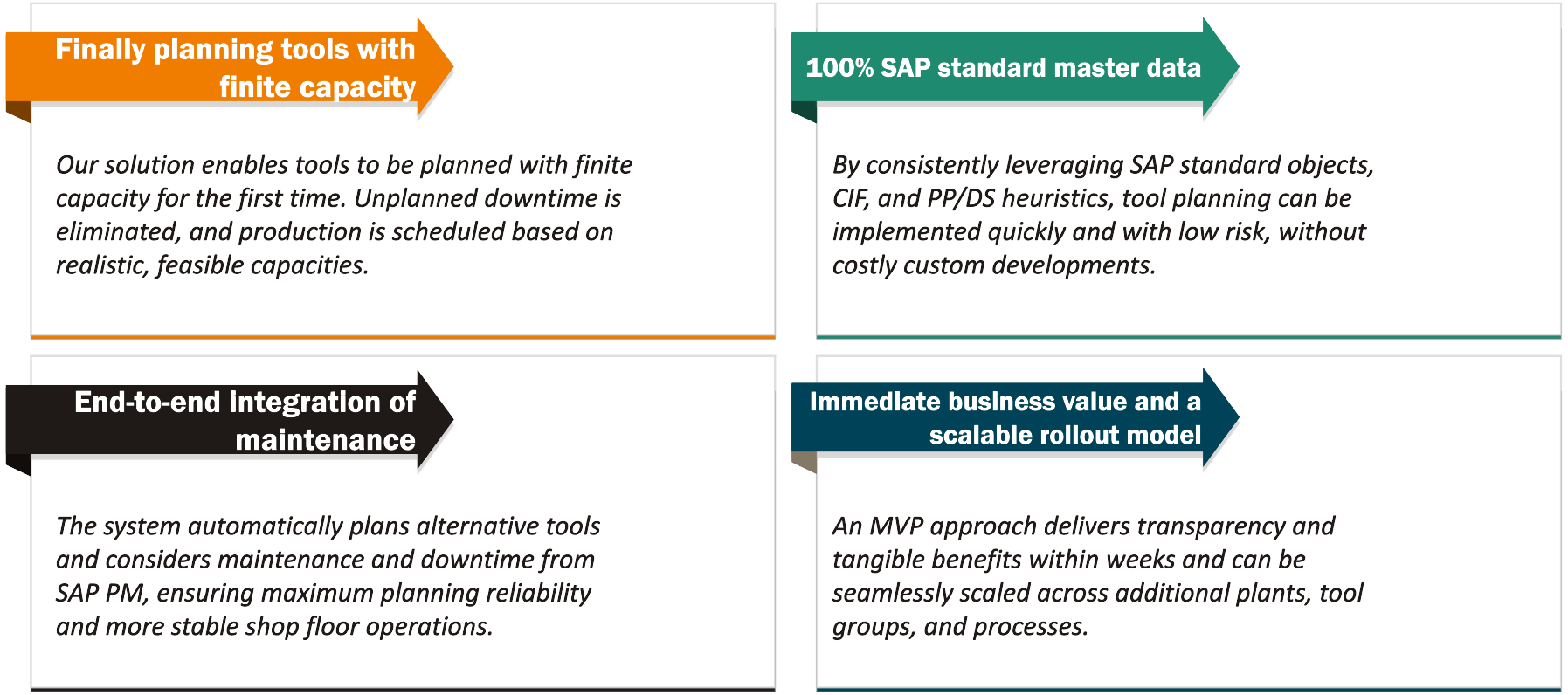

At a glance:

What makes our SAP PP/DS solution for planning production resources different

Our extension for SAP PP/DS enables end-to-end finite planning of tools, molds, and inspection equipment for the first time. The logic remains fully aligned with SAP standard and integrates seamlessly into existing SAP processes.

Core elements of the solution:

- Tools are modeled as finite resources, comparable to machines

- Maintenance and downtime are automatically considered in planning

- Standard master data links work centers and tools

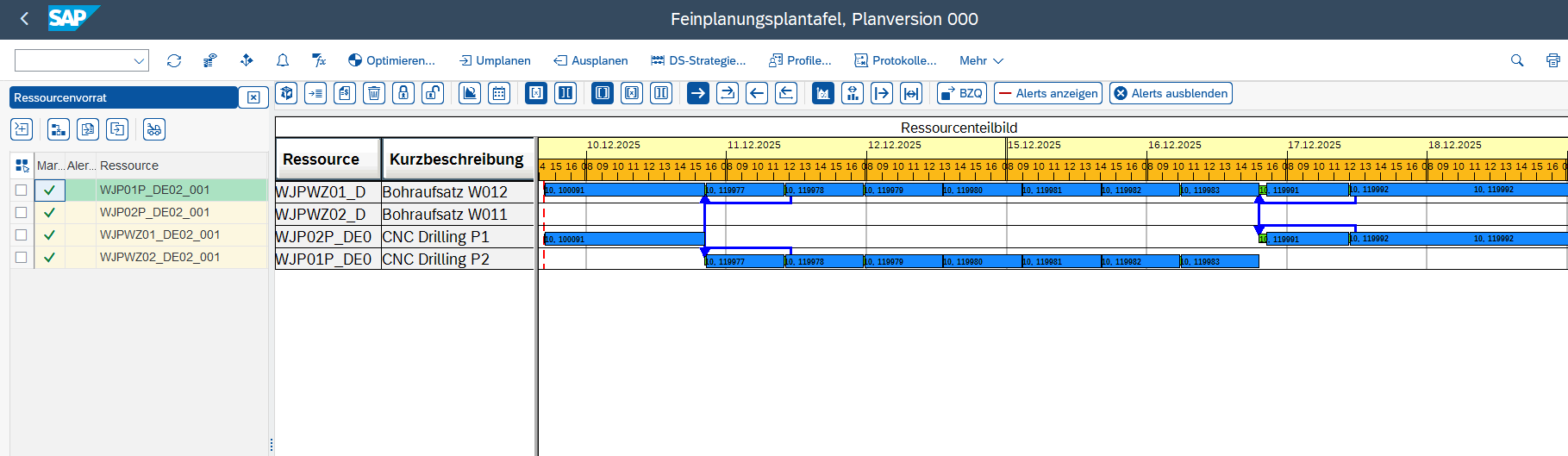

- PP/DS planning boards are used for sequencing

- Sister tools can be planned automatically as alternatives

- Full integration with SAP modules such as PM (Plant Maintenance) and MDM

This results in a transparent and reliable planning model for short- and mid-term production.

Technical Implementation Based on SAP Standard

The technical architecture is strictly based on SAP standard. Tools are transferred into the ePP/DS master data model via CIF integration and managed there as plannable resources. The foundation is the mobile work center concept, which we extend to equipment while remaining fully SAP-compliant.

By assigning tools to routing operations, a direct relationship between work center and tool is established and considered during detailed scheduling. Planning changes immediately impact capacity and utilization in real time. In case of bottlenecks, the system uses alternative production versions and therefore alternative tools. The result is a robust, flexible, and future-proof solution without custom code or complex proprietary logic.

During master data transfer, tools and work centers are linked so that they are always planned together during rescheduling and their dependency is preserved.

Practical Business Value

Planners gain a complete and reliable view of all relevant resources. They can immediately see where a tool is located, how highly it is utilized, and which alternatives are available. At the same time, the integration into SAP standard logic enables natural setup time optimization, as tool availability and work center capacity are considered together for the first time.

Key benefits at a glance:

- Transparency: Location, availability, and utilization of all tools are visible at any time

- Planning reliability: Finite consideration of tools significantly reduces delays and short-term replanning

- Flexibility: Suitable alternatives are automatically proposed in case of bottlenecks

- Integration: Maintenance and downtime from SAP PM are considered without additional effort

- Scalability: Start with an MVP and expand to additional plants and tool groups

- Ease of implementation: Based on standard master data and PP/DS BAdIs, without extensive customizing

These benefits impact different roles in distinct ways. Capacity planners benefit from a complete resource overview and more precise decision-making. Plant managers achieve higher asset availability and more stable production flows. At COO level, delivery performance and cost efficiency improve significantly as ad-hoc measures and unplanned downtime are reduced.

Typical Entry Scenarios

Companies typically start from different situations:

- ePP/DS is already in use: the tool logic complements the existing planning board with minimal effort

- S/4HANA is implemented, ePP/DS is not yet active: tool planning is integrated from the start

- A transformation project is ongoing: tool planning can be embedded directly into the new PP/DS process landscape

What matters most is anchoring tool planning as an integral part of production planning.

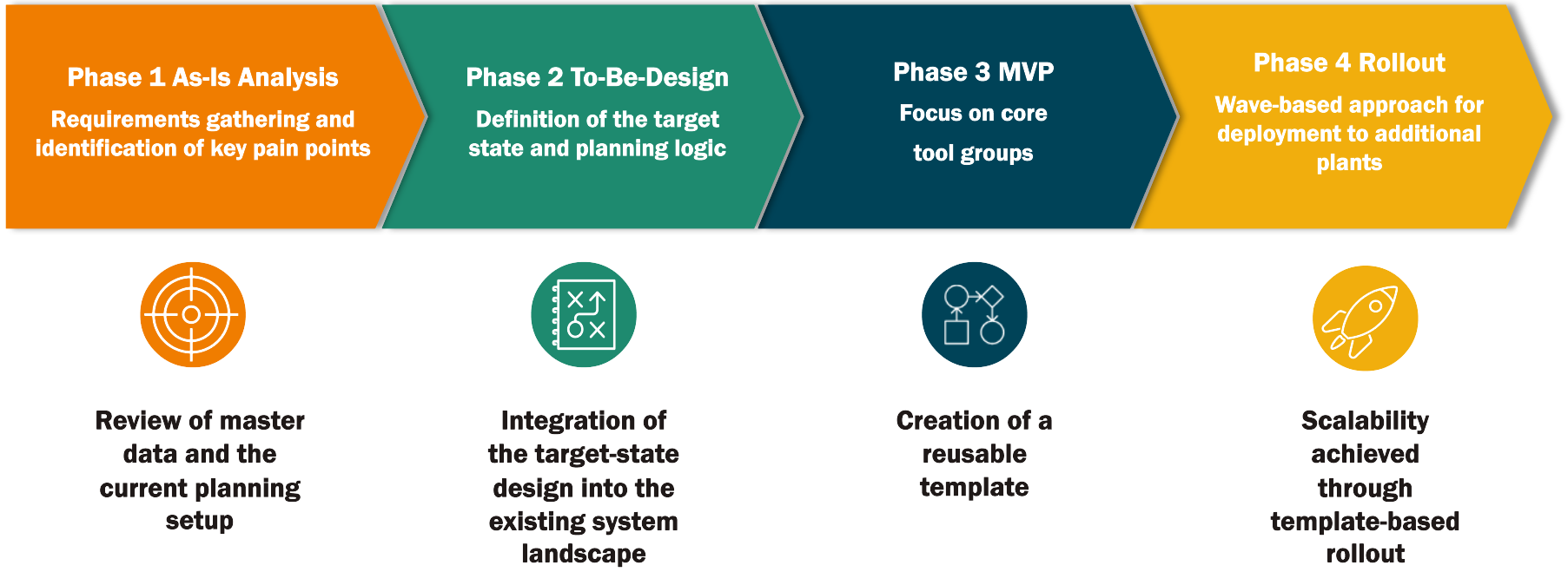

The cbs Approach

Our approach starts with an analysis of master data and processes. Typical bottlenecks such as missing tool availability or unclear responsibilities are identified.

Phase 1: As-Is Analysis

We review master data, understand the current planning setup, and capture typical pain points such as missing tool transparency or unclear ownership.

Phase 2: To-Be Design

Based on this, we define a target state, design the planning logic for production resources, and integrate it into PP/DS heuristics in a standard-compliant way. Training of planning roles is also part of this phase.

Phase 3: MVP Implementation

We deliberately start lean, focusing on key tool groups and closely supporting the go-live. Transparency on the effectiveness of the solution is achieved quickly.

Phase 4: Rollout

The concept is then expanded step by step across additional plants, tool groups, or process variants. If required, multi-stage tools or adjacent modules can also be integrated.

This results in a holistic and future-proof planning model that grows with the company’s requirements.

Integration into the SAP Landscape

The solution integrates seamlessly into SAP PM, MDM, and PP. Maintenance windows are automatically considered, master data remains standard-compliant, and the planning board provides an end-to-end view combining machines and tools.

Conclusion

Finite planning of production resources is not an add-on but an essential building block of modern production control. Our solution integrates this capability seamlessly into SAP PP/DS. The result is transparency, planning reliability, and scalability without complex custom developments.

Want to Learn How to Plan Tools with Finite Capacity and Check Your Master Data Readiness?

We offer two compact entry formats:

Readiness Check

Gain full clarity on how well your master data and planning processes are prepared for tool planning today. Together with your experts, we identify the key levers and bottlenecks and provide a clear, prioritized recommendation on how to make your planning more efficient, stable, and future-proof. The readiness check shows not only the current state but also the fastest path to measurable improvements.

Look & Feel Workshop

Experience live within just two hours how tool planning works in SAP. Using a realistic example, we demonstrate the interaction between work center, tool, and capacity in a transparent, intuitive, and fully standard-based way. You will immediately see the efficiency potential in your processes and the concrete improvements achievable with the solution. The workshop provides inspiration, a solid decision basis, and a tangible picture of your future planning setup.

Contact us to learn more and explore together how your production planning can take the next step.