Global supply chains are under pressure: increasing complexity, volatile markets, and scarce materials. While many companies still work with disconnected planning and confirmation processes, a new SAP reference architecture demonstrates a better approach. By deeply integrating SAP Integrated Business Planning (IBP) and SAP Advanced Available-to-Promise (aATP), a seamless end-to-end process is created that links planning, capacity, and order confirmation in real time. A concrete implementation example from a globally operating large enterprise in the electrical engineering and industrial automation sector shows how this future-oriented architecture already delivers reliable commitments, stable processes, and higher customer satisfaction.

From Forecast to Confirmation: How SAP is redefining Integrated Planning and Confirmation Processes

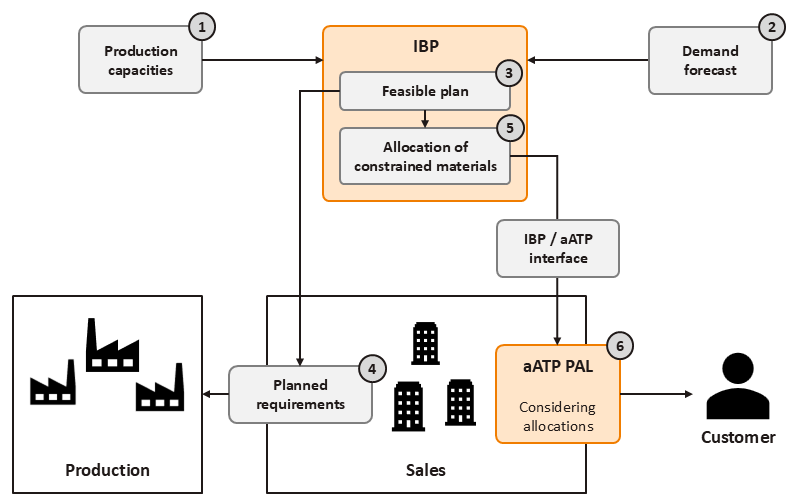

SAP has recognized this challenge and, with the combination of SAP Integrated Business Planning (IBP) and SAP S/4HANA Advanced Available-to-Promise (aATP), is pursuing an integrated architecture that addresses exactly this interface. SAP enables us to closely link planning and confirmation processes, thereby achieving consistent, realistic delivery commitments. IBP provides a coordinated, capacity- and material-based plan, while aATP uses this planning information in real time for order checking and confirmation, considering allocations, constraints, and priorities.

The advantages of this integration path can be seen in the example of a large enterprise in the electrical engineering and industrial automation sector. In its ongoing S/4HANA transformation project, the company follows a two-pillar approach that reflects the company’s different production scenarios: Make-to-Stock (MTS) and Make-to-Order (MTO).

MTS Scenario: Constraint Management through Allocations

In make-to-stock scenarios, SAP IBP supports proactive planning by identifying potential constraints and defining quantity frameworks and allocations based on available capacities. These specifications are then passed to SAP aATP and considered during the order confirmation process. As a result, aATP can confirm customer orders and stock transfer requests only within the planned allocation limits. This mechanism ensures stable delivery commitments and prevents over-confirmation, even when demand or capacity fluctuates.

MTO Scenario: Capacity Allocation for Order-Based Production

In make-to-order scenarios, the focus is on aligning capacities between planning and order entry. IBP provides aggregated information on available production resources and derives capacity allocations for relevant product groups or manufacturing areas. aATP accesses this capacity information during order processing and checks whether an order can be fulfilled within the planned resources. In this way, a seamless connection between planning and confirmation logic is created – a crucial step toward realistic and reliable delivery commitments.

These two pillars – allocation management (MTS) and capacity allocation (MTO) – demonstrate how flexibly the integration between IBP and aATP can be designed. With the IBP aATP integration, SAP provides a practical and scalable path to closely link planning and confirmation processes without compromising individual requirements.

The advantages are clear: more reliable commitments, better resource utilization, fewer coordination efforts, faster reactions to demand changes, and higher customer satisfaction.

The combination of SAP IBP and SAP aATP is not a rigid model but a flexible framework for integrated planning and confirmation processes. We would be happy to share our insights on the necessary adjustments, extensions, and potential pitfalls – and how to design the optimal solution for your specific scenario.